Introduction: The "Recipe" for Chaos

Manufacturing is arguably the hardest type of business to run.

If you are a retailer, life is simple: You buy a chair, you sell a chair. But if you are a manufacturer, you buy wood, fabric, screws, glue, and varnish. You pay a worker to cut the wood. You pay another to stitch the fabric. You assemble it. And then you sell a chair.

You aren't just managing inventory; you are managing a Transformation.

For many small manufacturers—whether you are bottling hot sauce, assembling electronics, or building custom furniture—this process is currently managed on a terrifyingly complex spreadsheet. You have one tab for "Raw Materials," another for "Finished Goods," and a lot of guesswork in between.

The problem? Spreadsheets don't understand recipes. They don't know that if you build 10 chairs, you need to automatically deduct 40 legs and 100 screws from your inventory.

This disconnect leads to the two biggest nightmares in manufacturing:

- Production Stoppages: You are halfway through an order and realize you are out of glue.

- Pricing Errors: You think your product costs $50 to make, but it actually costs $65 because you forgot to account for waste and labor.

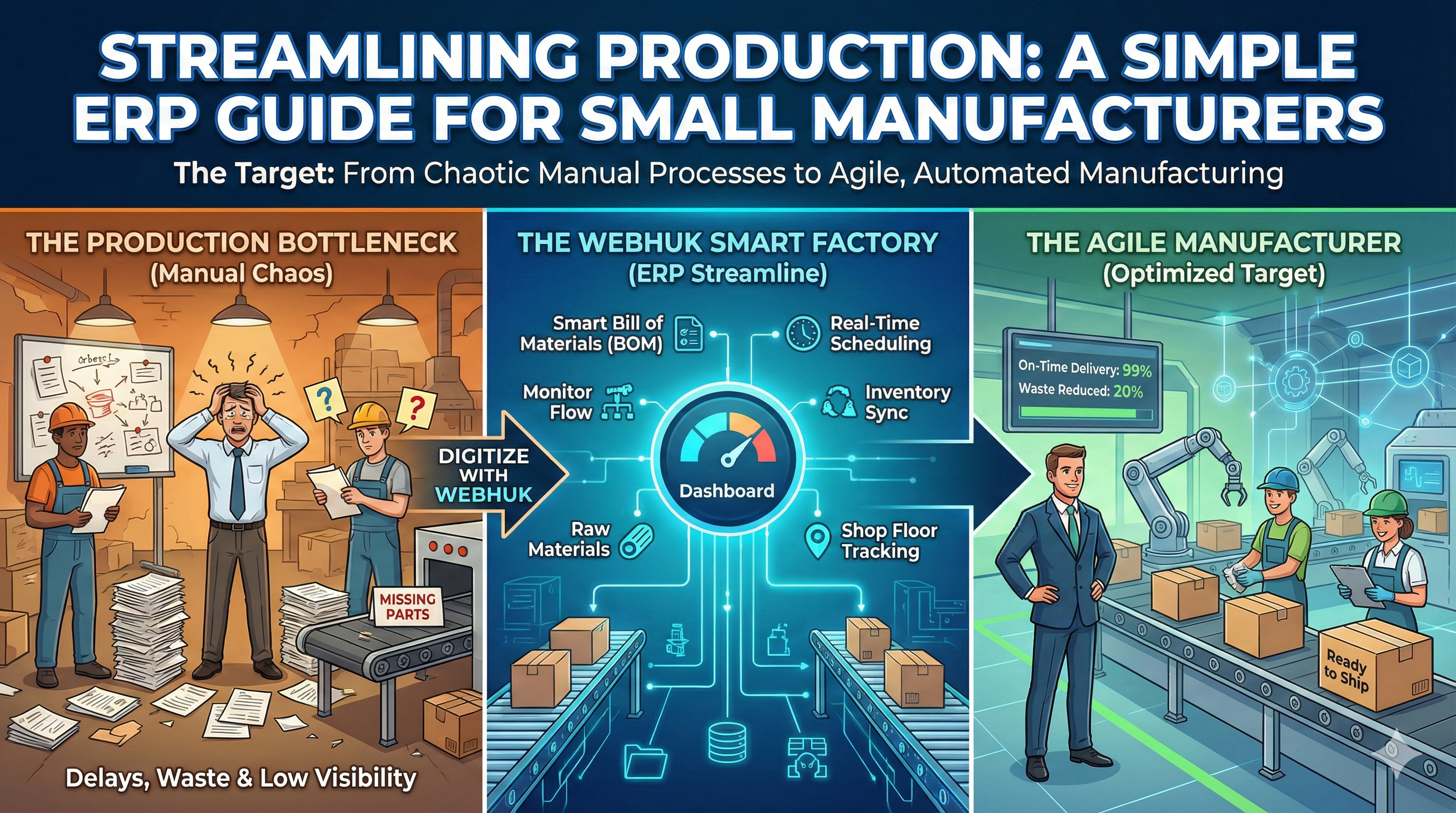

In this guide, we will explore how Cloud ERP simplifies this complexity. We will look at how to digitize your "Bill of Materials" (BOM) and gain total control over your production line.

The Core Concept: What is a "Bill of Materials" (BOM)?

Before we talk about software, we need to talk about the BOM. Think of the BOM as your "Master Recipe." It tells your system exactly what goes into making one unit of your finished product.

Example: A Custom Bicycle

- Frame: 1 Unit

- Wheels: 2 Units

- Handlebar: 1 Unit

- Screws: 12 Units

- Labor: 2 Hours

Why Excel Fails at BOMs: In Excel, these are just static text lists. If you get an order for 50 Bicycles, you have to manually calculate: "Okay, 50 x 12 screws = 600 screws. Do I have 600 screws? Let me check the other spreadsheet..."

It is slow, manual, and prone to error.

How ERP Handles BOMs: In a system like Webhuk, you define this recipe once. When you receive an order for 50 Bicycles, the system instantly looks at your stock and tells you: "You have enough Frames and Wheels, but you are short 200 Screws. Should I order them now?"

The 3 Stages of Manufacturing Inventory

To get control of your factory floor, you need to stop treating all inventory as the same. In an ERP, inventory lives in three distinct states:

1. Raw Materials

These are the ingredients sitting on your shelf (e.g., the wood, the fabric). They have a cost, but they aren't "for sale" yet.

2. Work-in-Progress (WIP)

This is the "Black Hole" for most small businesses. These are items that are currently being built. They aren't raw materials anymore, but they aren't finished goods either.

- The Trap: If you don't track WIP, you don't know the value of the goods sitting on your workbench.

3. Finished Goods

This is the final product ready to be shipped to the customer.

The ERP Workflow: When you click "Start Production" in Webhuk:

- The system deducts items from Raw Materials.

- It temporarily moves value to WIP.

- When production is done, it adds the item to Finished Goods. This movement happens automatically, ensuring your financial reports are always accurate.

The "Hidden Cost" of Manufacturing

Why do so many small manufacturers struggle to make a profit? Often, it is because they don't know their True Product Cost.

They calculate cost like this:

- Wood: $10

- Fabric: $5

- Total Cost: $15

- Selling Price: $30

- Profit: $15 (Great!)

But they forgot:

- Labor: It took a technician 1 hour ($12/hr) to build it.

- Overhead: The electricity to run the saw and the rent for the factory ($2).

- Waste: You threw away 10% of the fabric cuttings ($0.50).

Real Cost: $15 + $12 + $2 + $0.50 = $29.50 Real Profit: $0.50.

You are doing all that work for fifty cents.

The Webhuk Fix: A good ERP allows you to add "Landed Costs" and "Labor Costs" into your BOM. When you build the product, the system sums up everything—materials, labor, and overhead—to give you a precise "Cost Per Unit." You might discover that your best-selling product is actually losing you money.

Production Planning: Never Miss a Deadline

The other major benefit of ERP is Planning. When a customer calls and asks, "Can you deliver 100 units by next Friday?"—how do you answer?

- Without ERP: You run to the warehouse, check the shelves, ask the floor manager, and guess: "Maybe?"

- With ERP: You check the "Production Planner."

The system looks at:

- Current Stock levels.

- Incoming Supplier Orders (when will the screws arrive?).

- Current Production Queue (what are we building right now?).

It gives you a data-backed answer: "We can build 60 units by Friday, but we are waiting on a shipment of Wheels for the remaining 40. We can deliver the full order by Tuesday."

This honesty builds trust with clients.

Kitting & Bundling: The "Light Manufacturing" Solution

Not every manufacturer needs a system to build a Boeing 747. Many SMEs do "Light Manufacturing" or "Kitting."

- Example: You sell Gift Baskets.

- You buy Shampoo, Soap, and a Towel.

- You put them in a Basket.

- You sell the "Luxury Spa Set."

Webhuk is built specifically for this type of Assembly. You can create a "Kit" (The Spa Set). When you sell the Kit, Webhuk automatically deducts the Shampoo, Soap, and Towel from inventory. You don't need complex engineering software; you just need smart inventory logic.

5 Signs You Need Manufacturing ERP

If you are unsure if you are ready to upgrade from Excel, check if you have these symptoms:

- The "Negative Stock" Mystery: Your spreadsheet says you have -5 screws. (Impossible, but common in Excel).

- The Waste Problem: You have piles of scrap material that aren't accounted for financially.

- The "Busy Work" Trap: You spend more time updating spreadsheets than building products.

- Sales vs. Production Arguments: Your sales team sells things that Production can't build because parts are missing.

- Profit Confusion: You have high revenue but low cash, and you don't know which product is leaking money.

Conclusion: Build Smarter, Not Harder

Manufacturing is a beautiful business. You are creating value out of raw parts. But to scale a manufacturing business, you have to move from "Art" to "Science."

You cannot rely on memory or manual lists to manage a complex supply chain. You need a system that acts as the brain of your factory.

By implementing a specialized ERP for Small Manufacturing, you gain:

- Visibility: Know exactly what is on the shelf.

- Accuracy: Know exactly what a product costs to make.

- Efficiency: Never stop the line because of a missing $1 part.

Stop guessing. Start measuring.

Streamline Your Production Line

Webhuk.io is designed for Makers, Assemblers, and Light Manufacturers.

- Simple BOM Management.

- Auto-Deduct Raw Materials.

- Real-Time Costing.

Start Your 7-Day Free Trial – Digitize your recipes today.

Frequently Asked Questions

1. Why can’t I just keep managing my production on Excel?

You can, but it is risky. Spreadsheets are static; they don't understand the relationship between parts. If you sell 50 bicycles, a spreadsheet won't automatically deduct the 100 wheels and 600 screws from your inventory unless you do it manually. That manual entry is where human error happens. An ERP automates this "deduction" logic, ensuring you never accept an order you can't actually build.

2. What exactly is a "Bill of Materials" (BOM) in simple terms?

Think of a BOM exactly like a cooking recipe. If you are baking a cake, the recipe lists flour, eggs, sugar, and the time it takes to bake. In manufacturing, the BOM lists every raw material (wood, screws) plus the labor time required to create one finished product. It is the "source of truth" that tells the software exactly what to subtract from your stock when you hit "Produce."

3. I have high revenue, but my profits are low. Can software fix this?

It can certainly diagnose it. Many small manufacturers calculate profit by only looking at the cost of materials (e.g., "The wood cost $10"). They forget to add the "invisible" costs like electricity, rent, waste, and labor time. An ERP helps you load these "Landed Costs" into your product data. You might find out that a product you thought was profitable is actually costing you money once you factor in the labor.

4. Is this software only for heavy industrial factories?

Not at all. "Manufacturing" covers anyone who puts things together. If you run a business that bundles shampoo and soaps into "Gift Baskets," that is manufacturing (specifically called "Kitting"). If you assemble custom PCs, that is manufacturing. If you take raw components and transform them into something new, you need a system that tracks that transformation, regardless of your size.

5. What happens if I try to build something but I’m missing one part?

This is the dreaded "Production Stoppage." Without software, you usually find out you are missing a part when you are standing on the factory floor, which stops work immediately. With Webhuk, the system checks your inventory before you start. It will alert you: "You have enough wood, but you are short on glue. Order now?" This allows you to fix the shortage before it kills your deadline.